Categories

New products

-

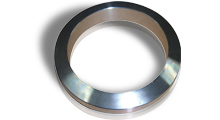

Lens Ring Joint Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Lens Ring Joint Gasket manufacturers in China, welcome to wholesale low price Lens Ring Joint Gasket from our factory

-

Double Jacket Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Double Jacket Gasket manufacturers in China, welcome to wholesale low price Double Jacket Gasket from our factory

-

Corrugated Gaskets

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Corrugated Gaskets manufacturers in China, welcome to wholesale low price Corrugated Gaskets from our factory

-

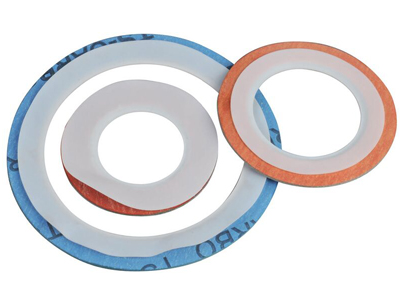

PTFE Envelope Gasket

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading PTFE Envelope Gasket manufacturers in China, welcome to wholesale low price PTFE Envelope Gasket from our factory

-

Rubber Sheet

Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading Rubber Sheet manufacturers in China, welcome to wholesale low price Rubber Sheet from our factory

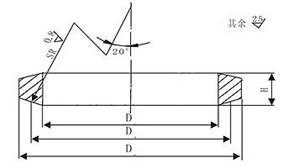

Lens Ring Joint Gasket

> Lens ring joint used in higher pressure than 3,000 lbs. > These gaskets had been used on pipe flanges in synthesizing line.

Lens Ring Gasket, also known as washer with ball face, is mainly used for the high pressure pipe connections. The primary function of lens ring gasket is to seal. Metal lens gaskets includes metal flat gasket, triangular gasket, double cone ring, C-ring and C type gasket, ring gasket, serrated gasket, wave gasket and hollow o-ring, etc..

Perforated lens ring gasket is used for the flange seal of high pressure pipe. Blind lens ring gasket is used for the blind flange seal of high pressure pipe. The materials of lens ring gasket use the forgings, rolled materials and pipes. Blind lens ring gaskets use the forgings.

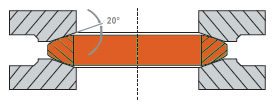

It is wide to use the lens ring gaskets to seal in the high pressure pipe connections. Seal faces of lens ring gaskets are ball surface, in contact with conical sealing surface of the pipe, the initial state is in a loop. By the action of the preload force, lens ring gasket has a plastic deformation at the contact point and the loop is into a belt loop, which has the better sealing performance. The contact face is naturally formed by spherical surface and beveled surface, so the gasket is easy for alignment. Lens ring gasket is the forced sealgasket.

Structural Form

Features

1.Lens ring gasket is applicable for the pipe seal that the pressure isn't lower than 10MPa.

2.Lens ring gasket is of line seal, large expansion and contraction, large compensation and easy compact.

3.Due to contact with flange cone face, easy to have the pressing mark. The interchangeability of part is poor.

4.Lens ring gasket is also pressure energized, as well as the double-cone gasket.

5.The hardness of lens ring gasket must be15~20HB lower than the mating flange face hardness.

Performance Parameters

|

gasket factor |

m=5.50-6.50 |

|

gasket using pressure |

<=32MPa |

|

gasket using temperature |

-196oC - 1000oC |

|

minimum pre-tightening pressure |

y=126.6 - 182.8MPa |

Materials

Soft Iron, Low C/S, ss410, ss304, ss316, ss347, F5, F11, Copper, Aluminum, Inconel 600, Inconel 625, Incoloy 800, Incoloy 825, Monel 400, Titanium, Nikel 200, Hastelloy C276, Zirconium702

Application

The gaskets are primarily used in the oil, gas, petrochemical and offshore industries. They are also commonly used on valves, pipe-work assemblies and vessel joints and are used to seal flanged connections subject to high pressures and temperatures.

Technical Standards

It can provide any standard and non-standard sizes, including the standards of API 6A, ASME B16.20, DIN 2693-67, JPI-7S-23-72,DIN-2696-1999 and other standards.